CSA E920-98 pdf download – Ballasts for tubular fluorescent lamps General and safety requirements Numéro de référe.nce Reference number CEI/IEC 920: 1 990 (reaffirmed / confirmée.

2. 8 CIrcuit power factor. Symbol X Power factor of the combination of a ballast and the lamp or lamps for which the ballast is designed. 2.9 High power factor ballast Ballast having a circuit power factor of at least 0.85 (leading or lagging). No±e.- The value 0. 85 takes into account the distortion of the current waveform. For North America high power factor is defined as a power factor of at least 0. 9. 2. 10 High audiofrequency impedance ballast Ballast of which the impedance in the frequency range 250 Hz to 2 000 Hz exceeds the values specified in IEC Publication 921 , to avoid interference with power line signals. 2. 1 1 Low distortion ballast Ballast of which the harmonic content complies with the more severe requirements specified in IEC Publication 921 .

2. 15 Chauffage (ou préchauffage) en parallè/e d’une cathode Type de chauffage (ou de préchauffage) fourni par un enroulement a basse tension du ballast directement connecté aux bornes de cathode de Ia lampe. Note.- Ce type de circuit de chauffage n’ es± en pratique utilisé qu’ avec des lampes fonctiannant sans starter. 2. 16 Chauffage (ou préchauffage) en série d’une cathode Type de chauffage (ou de préchauffage) dans lequel Ia cathode est insérée en série dans le circuit principal avant que Ia lampe s’amorce. 2. 1 7 Effet redresseur Effet pouvant se manifester a Ia fin de Ia durée de vie dune lampe lorsque l’une des cathodes est brisée ou a une emission thermoélec- trique insuffisante, de telle sorte que le courant qui traverse Ia lampe présente des demi-périodes successives constamment I néales. 2. 1 8 Puissance de court-circuit La puissance de court-circuit d’une source de tension est le quotient du carré de Ia tension disponible a ses bornes de sortie (a circuit ouvert) par l’impédance interne de Ia source (vue des mêmes bornes). 2.1 9 Essal de type Essai ou série dessais effectués sur un échantillon d’essai de type, afin de verifier Ia conformité de Ia conception dun produit donné aux prescriptions de Ia norme correspondante. 2.20 Echantillon d’essai de type Echantillon compose d’une ou de plusieurs unites identiques, pré- sentées par le fabricant ou le vendeur responsable, afin de les soumettre aux essais de type.

2. 1 5 Parallel cathode heating (or pre-heating) Type of heating (or pre-heating) supplied by a low tension winding of the ballast directly connected to the cathode terminations of the lamp. Mote. – This type of heating circuit is used in practice only with lamps operated without starter. 2. 16 Series cathode heating (or pre-heating) Type of heating (or pre-heating) in which a cathode is connected in series in the main circuit before the tamp has started. 2. 1 7 Rectifying effect Effect which may occur at the end of lamp life when one cathode is either broken or has insufficient electron emission, resulting in the arc current being constantly unequal in consecutive half-cycles. 2.1 8 Short-circuit power Short-circuit power of a voltage source is the quotient of the square of the voltage produced at its output terminals (in open circuit conditions) and the internal impedance of the source (as seen from the same terminals). 2.1 9 Type test Test or series of tests, made on a type test sample for the purpose of checking compliance of the design of a given product with the requirements of the relevant standard. 2.20 Type test sample Sample consisting of one or more similar units submitted by the manufacturer or the responsible vendor for the purpose of a type test.

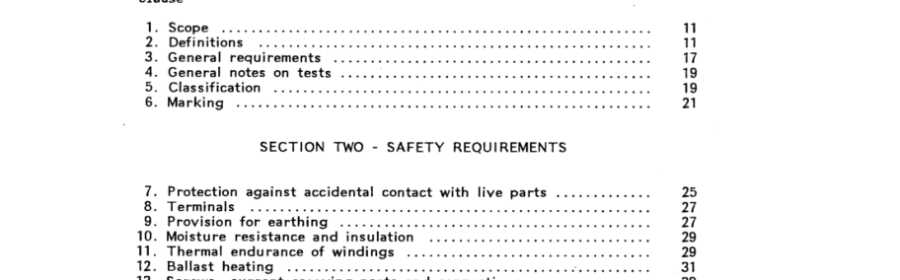

3. General requirements Ballasts shall be so designed and constructed that in normal use they operate without danger to the user or surroundings. Capacitors and other components incorporated in ballasts shall comply with the requirements of the appropriate IEC standard. Thermally protected ballasts shall comply with the requirements of Appendix B. In general, compliance for ballasts and other elements is checked by carrying out all the tests specified. In addition, the enclosure of independent ballasts shall comply with the requirements of IEC Publi- cation 598-1 , including the classification and marking requirements of that standard.CSA E920-98 pdf download.