CSA C83-96 pdf download – Communication and Power Line Hardware.

3.1 .4 Terms relating to sampling procedures are defined in Clause Al .4 of Appendix A. 3.2 Definitions The following definitions apply in this Standard: Bending—a forming operation where the mill bar is not reduced in section by more than 1 0%. FATT (Fracture Appearance Transition Temperature)—the temperature at which metal fracture characteristics change rapidly such as from primarily fibrous (shear) to primarily crystalline (cleavage) fracture. 50% FATT indicates the temperature at which fracture surface is 50% fibrous (shear) and 50% crystalline (cleavage). Forgings—items which are formed from steet bars or billets, using open or closed dies, other than simple bending. Fracture load, ultimate load, breaking load, and failure load—load which causes a break allowing separation into two parts. Bending alone does not constitute a failure. Nominal—the size designation used for general identification by specifying a raw stock size. Threaded fastener torques— Failure torque—the minimum value of applied torque at which or after which any component fractures. Installation torque—the lowest value of tightening effort under which the device would be installed. Reusability torque—the threshold value of applied torque at which any component of the items shows permanent deformation (induding thread deformation sufficient to destroy fingerfree fit). Note: Field installation torque values are expected to range between installation and reusability values. Reusability load—the greatest load that may be applied to the item under test without producing permanent deformation so as to prevent disassembly by hand.

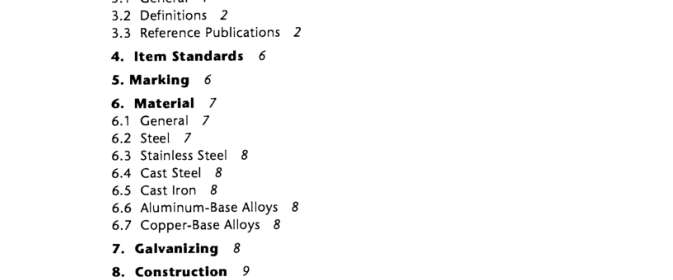

4. Item Standards 4.1 Each item of hardware is covered by a separate Standard, which usually consists of text and a drawing. The text normally includes test requirements and a classification of defects based on acceptable quality level (AQL) values. 4.2 To permit freedom of design, drawings, in general, are schematic and show only the details and limiting dimensions required to ensure functional compatibility with other standard items. Where dimensions are shown as “maximum” or “minimum”, they are intended as extreme limits and are based on considerations of fit. Such values should not be construed as nominal dimensions or as necessary or optimum design values for strength or other mechanical requirements. Mechanical characteristics are specified by performance tests wherever practicable. Where performance tests are not practicable, additional details of design and materials are specified. In either case, the dimensions and tolerances shown on the drawing form part of that Standard’s requirements. 5. Marking 5.1 Hardware items shall be permanently marked to identify the fabricator and nomina’ strength rating of the items, unless size or shape makes marking impracticable. If marking is not required, it will be so indicated in the Item Standard. 5.2 Hardware items that require marking after fabrication, such as yoke plates and mild steel items, may be marked by indenting stamps.

6. Material 6.1 General The type of material shall be as shown in the Item Standard, and shall be such that the finished items will meet the performance requirements of the item Standard. The material shall conform to the following general requirements given in this Clause for type and to the specific requirements of the grade, class, or alloy. The purchaser shall specify the Level 2 (Toughness) of energy absorption/toughness in Clause 6.2.4 if required. 6.2 Steel 6.2.1 Line hardware shall be manufactured from commercially available steel that, on ladle analysis, contains not more than 0.04% phosphorus or 0.05% sulphur; except that, for bolt and nut stock, up to 0.1 5% sulphur by ladle anafysis may be permitted. Steels may exceed these limits on recheck analysis and should not be subject to rejection for phosphorus or sulphur unless misapplication is clearly indicated. 6.2.2 To avoid hydrogen embrittlement, the ultimate tensile strength shall not exceed 1 000 MPa. 6.2.3 All steel plates shall be made of structural steel conforming to the general requirements of CSA Standard CAN/CSA-G40.21 , Category 2 or Category 4. Minimum yield strength shall be 350 MPa.CSA C83-96 pdf download.