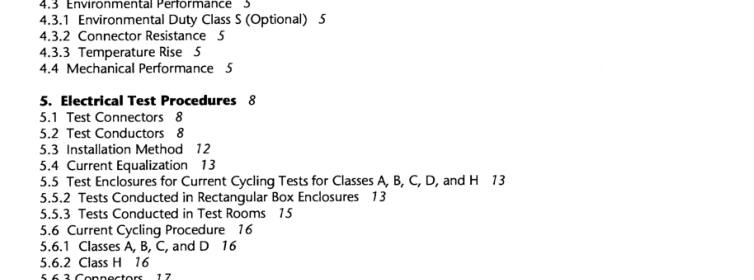

CSA C57-98 pdf download – Electric Power C onnectors for Use in Overhead Line Conductors.

2. Reference Publications This Standard refers to the following publications and where such reference is made it shall be to the edition listed below, induding all amendments published thereto. CSA Standards CAN/CSA-C49.1-M87 (R1993), Round Wire, Concentric Lay, Overhead Electrical Conductors. ASTM* Standards B 117-94, Practice for Operating Salt Spray (Fog) Testing Apparotus; E 4-96, Force Verification of Testing Machines. *American Society for Testing and Materials 3. Definitions 3.1 The following definitions apply in this Standard. Adaptor – a device for modifying the method of attachment or the size of accommodation of a connector. Armour – hardware that is installed over a conductor for mechanical reinforcement or protection. Brazed device – – a device that is attached or istalld by brazing. Cold resistance – the resistance measured at the end of the current OFF cycle at the steady-state ambient temperature.

Note: A typical application might be as fllows: Connectors for 115 kV lines Duty Class A, Enironmental Duty Class s, and Mechanical Duty Class 1 Connectors for 12 kV lines Duty Class A and Mechanical Duty Class 1 Connectors for 240 V secondaries Duty Class B and Mechanical Duty Class 2 Equalizer – – a device inserted in or attached to a conductor to equalize the current distribution in the strands of the conductor, thus providing an equipotential plane. Forging pressure – the output force of the insalltion compression tool divided by the projected area of the die cavity (width x bite length). Hot resistance – – the resistance measured immediately at the end of the current ON cycle. Pressure contact – a contact fabricated into the connector during manufacture and providing the sole means of current transmission between two component parts of the connector. Reusable torque strength – – of a bolted connector, means the threshold value of applied torque at which permanent deformation of any part occurs that would affect the performance or reinstallation of the connector. Separator – a component of a connector used to prevent intimate contact of the conductors. Sleeve – – a tubular connector or a tubular component of a connector (may be a fll or non-tension device). Stirrup一a ftting for joining to a conductor and providing a copper bar or post to which a lve-line connector may be attached. Ultimate torque strength – – of a bolted connector, means that value of applied torque at which failure of any component occurs.

4.2.2 Electrical Duty Class A, B, C, and D 4.2.2.1 The connector resistance, measured as described in Clause 5.8, shall show a condition of stability between the 25th cycle and the completion of the current cycles required in Table 1. Stability is achieved if any resistance measurement, including allowance for measurement error, does not vary by more than +5% from the average of all the measurements in this interval. 4.2.2.2 The temperature of the connectors tested in accordance with Clause 5.7 shall not exceed the temperature of the control conductor (Figure 1). The temperature difference between the control conductor and the connector shall be stable between the 25th cycle and the completion of the number of cycles required in Table 1 for the connector class being tested. Stability is achieved if any temperature difference between the control conductor and the connector, including allowance for measurement error, is not more than 10°C below the average of all temperature differences for that connector in this interval.

4.2.3 Electrical Duty Class H (Optional) 4.2.3.1 Class H connectors are intended for use under severe operating conditions. 4.2.3.2 The connector resistance, measured as described in Clause 5.9, shall show a condition of stability such that there is no more than +5% variation from the average of the measurements in the hot resistance or in the cold resistance over the entire current cycling period indicated in Table 1. 4.2.3.3 The change in temperature rise of connectors, measured as described in Clause 5.7.2 and calculated in accordance with Clause 5.7.3, shall not, at any time, vary more than +5% from the average of the measurements over the entire current cycling period. 4.3 Environ mental’ Performance 4.3.1 Environmental Duty Class s (Optional) Connectors with Environmental Duty Class S designation are intended to be used in saline environment (for example, coastal areas).CSA C57-98 pdf download.