CSA C68.7-11 pdf download – Underground secondary and service-entrance cable for electrical distribution utilities.

3 Definitions The following definitions shall apply in this Standard: Aluminum conductor material (ACM) — AA-8000 series aluminum alloy conductor material in accordance with the physical and electrical requirements of ASTM B800. Cable — Type UBC 90 — underground secondary or service-entrance cable consisting of two, three, or four circuit conductors twisted together, one of which is an identified insulated neutral. Each conductor is insulated with XLPE and is unjacketed. Type UBC 90 is suitable for installation in conduit only. Type UDB 90 — underground secondary or service-entrance cable consisting of two, three, or four circuit conductors twisted together, one of which is an identified insulated neutral. Each conductor is insulated with XLPE and is unjacketed. Type UDB 90 is suitable for direct burial or installation in conduit. Type UNB 90 — underground secondary cable consisting of six phase conductors cabled around a neutral conductor. Each phase conductor is insulated with XLPE and may be jacketed or unjacketed. The neutral conductor may be bare or insulated with XLPE. Type UNB 90 is intended for secondary network systems. Type USEI 75 — underground secondary or service-entrance cable consisting of two, three, or four circuit conductors twisted together, one of which is an identified neutral. Each conductor is insulated with thermoplastic or thermoset polyethylene and is jacketed with PVC. Type USEI 75 is suitable for direct burial or installation in ducts.

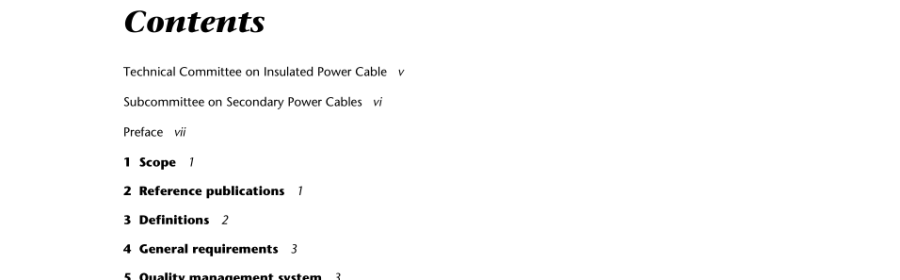

4 General requirements Unless otherwise specified in this Standard, cable shall comply with CSA C22.2 No. 52. 5 Quality management system A quality management system consists of all planned and systematic actions that are necessary to ensure that a product conforms to technical or performance-based requirements. The manufacturer should have a quality management system in place that conforms to the requirements of an acceptable quality program. Note: An example of an acceptable quality program is one based on CAN/CSA-ISO 9001. 6 Product qualification Cable shall be tested in accordance with Clause 8. Product qualification shall depend on evaluation of the test results. Capability tests shall be performed every 1 0 years or when a cable component material or design is changed. 7 Construction 7.1 General Types USEI 75 and USEI 90 cable shall comply with the material and construction requirements specified in CSA C22.2 No. 52. Types UBC 90, UDB 90, and UNB 90 cable shall comply with the material and construction requirements of this Standard.

7.2 Conductor Aluminum conductors shall be compact stranded and shall be of ACM in accordance with CSA C22.2 No. 38 or aluminum 1 350 intermediate temper in accordance with CSA C22.2 No. 52. Table 1 of this Standard shows the commonly used phase conductor sizes for cable made to this Standard. Full-size neutral construction should be used. Reduced neutral sizes may be supplied in accordance with Table 1 of CSA C22.2 No. 52. Copper conductors sized smaller than 500 kcmil shall be uncoated and compact stranded and meet the requirements of CSA C22.2 No. 38. Copper conductors sized 500 kcmil and larger shall be concentric round compressed stranded Class B or single input wire (SIW), with the direction of lay reversed in successive layers or with unilay or unidirectional lay.

7.5 Neutral conductors 7.5.1 Types USEI 75, USEI 90, UBC 90, and UDB 90 cable The insulated neutral conductor shall be constructed of the same material as the phase conductors. 7.5.2 Type UNB 90 cable The neutral conductor shall be constructed of the same material as the phase conductors. 7.6 Secondary network bundle assembly Type UNB 90 The network bundle assembly shall consist of six phase conductors cabled around a neutral. The lay length shall not exceed 1 5 times the assembled diameter of the cable (the assembled diameter shall be taken as the calculated circumscribed diameter over the complete, assembled conductor bundle). The transposition of the phase conductors shall be such that each conductor of the same phase shall lie diametrically opposite across the neutral. Conductor designation shall be as described by the 4-conductor cable assembly requirements given in Table 5. The phase conductors shall meet the requirements of (a) jacketed phase conductor construction of Type USEI 90, with at least one of the conductors marked in accordance with Clause 9.1 .1 ; or (b) unjacketed phase conductor construction of Type UBC 90 or UDB 90, with at least one of the conductors marked in accordance with Clause 9.1 .2. The neutral conductor may be bare or insulated.CSA C68.7-11 pdf download.