CSA HGV 4.3-2012 pdf download – Test Methods For Hydrogen Fueling Parameter] Eval luation.

1.1 Scope: This standard establishes the test method, criteria, and apparatus to evaluate a hydrogen fueling station as it relates to achieving the protocol specified in SAE TIR J2601 – 2010, Fueling Protocols for Light Duty Gaseous Hydrogen Surface Vehicles, for fueling, and the SAE TIR J2799, 70 MPa Compressed Hydrogen Surface Vehicle Fueling Connection Device and Optional Vehicle to Station Communications for communications with light duty vehicle hydrogen storage systems less than 1 0 kg (37.2 lbs). The testing evaluation applies to fueling stations designed to fill vehicle storage systems following the prescribed protocol defined in SAE TIR J2601 – 201 0 that targets rapid fills, while respecting temperature, pressure, and fuel density safety limits. For fueling stations with the capability for communications with the vehicle, these test methods include the approach to confirm the requirements specified in SAE TIR J2799/J2601 . Newly manufactured hydrogen fueling stations shall be tested according to this standard prior to initial operation of the station for fueling vehicles. This standard is also intended to provide test methods for validation of existing hydrogen fueling stations. Unless otherwise specified, the requirements in this document apply to the verification of SAE TIR J2601 – 201 0 compliant Hydrogen Fueling Stations (HFS). If the value for measurement as given in this standard is followed by an equivalent value in other units, the first stated value is to be regarded as the specification. All references to pressure throughout this standard are to be considered gauge pressures, unless otherwise specified.

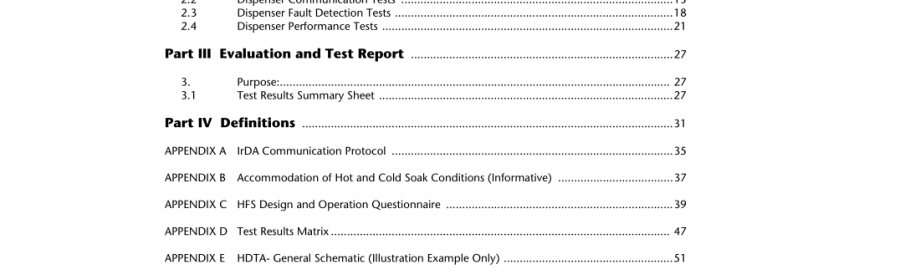

3. Purpose: To assure compliance and compatibility of the Hydrogen Fueling Station to the performance requirements of SAE TIR J2601 , a CSA HGV-4.3 Evaluation and Test Report will be completed. The purpose of this evaluation and test report is to document the Fueling Station design, mode of operation, and test results. The main sections of the report include the HFS Design and Operation Questionnaire, (Appendix C), The Results Summary Sheet (Section 3.1 ), Test Results Matrix (Appendix D), and the testing apparatus (Appendix E). The Design and Operation Questionnaire shall be completed in advance of field test whenever possible. Certification in accordance to HGV 4.3 requires the completion of all three sections. The Evaluation and Test Report provides the necessary compliance documentation and should be made available as evidence to the completion of HGV 4.3. The analysis of results summary should include the actual parameter values as indicated in section 2.1 . At the conclusion of the HGV 4.3 tests, the Test Results Matrix (Appendix D) shall be completed with the values from each test. The corresponding cells marked in the matrix are the parameters that are required to be provided for certain tests. The completed matrix will be used as the evidence for the results summary and included in the Evaluation and Test Report.

EQUIPMENT ACCURACY: The maximum equipment, system and dynamic inaccuracy (including both accuracy and precision) in the measurement of a physical state with respect to the true value of the variable being measured. ESD: Emergency Shut Down system including manual switches and automatically closing valves on all sources of hydrogen at the station. FILL PRESSURE: The maximum pressure attained at the actual time of filling. Fill pressure varies according to the ambient temperature, the temperature of the fuel being delivered to the dispenser and the initial pressure of the vehicle to be filled. FUELING EVENT: the process of a dispenser filling a vehicle (or HDTA test tank). Each fueling event will start with a pressure pulse to establish vehicle start pressure and check for leaks at the hose and nozzle/receptacle connecting point, and includes a smooth pressure ramp rise and ends when the vehicle tank pressure equals the target pressure calculated by the dispenser system. FUELING EVENT RECORD: When using the HDTA, a fueling event record includes 1 second samples during the Fueling Event and 1 minute samples of HDTA tank temperature and pressure for 30 minutes after the dispenser stops providing fuel to the HDTA test tank. FUEL DELIVERY TEMPERATURE: The temperature of the hydrogen gas as measured by the HDTA just downstream of the HDTA vehicle receptacle during the fueling event.CSA HGV 4.3-2012 pdf download.