CSA S406-92 pdf download – Construction of Preserved Wood Foundations.

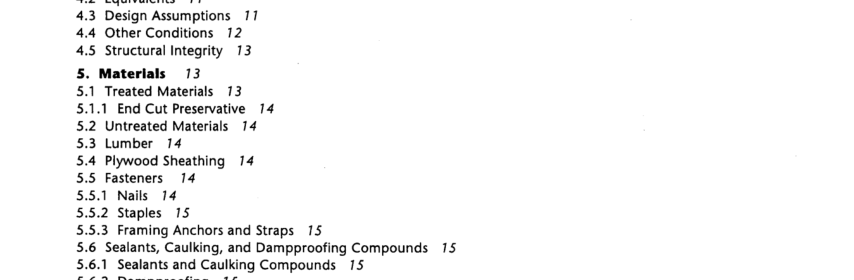

5.1.1 End Cut Preservative

The preservative used for field treating cut ends of lumber shall be a copper napthanate preservative solution prepared with a solvent conforming to CSA Standard CAN/CSA-080.201. The preservative solution shall contain a minimum of 2% copper metal.

Note: In order to obtain a 296 copper metal solution, a solution containing approximately 7796 copper nophthenote by weight is required. It may be obtained from or recommended by the supplier of the treated mat erial.

5.2 Untreated Materials

Lumber, plywood, and other wood based materials used in the following locations need not be treated:

(a) those portions of exterior walls which are more than 200 mm (8 In) above the adjacent exterior grade,

(b) floor structures more than 300 mm (12 in) above the granular drainage layer or interior ground level of a ventilated crawl space; and

(C) interior columns and partitions above a wood sleeper or suspended wood floor or above a concrete slab floor when separated from the concrete by a dampproofing material.

Note: These guidelines result in good performance unless there are special conditions conducive to decoy.

5.3 Lumber

Softwood lumber used in the exterior wall as studs or as horizontal structural framing resisting lateral soil loads shall be No. 2 grade or better, graded in accordance with NLGA Standard Grading Rules for Canadian Lumber; shall be grade stamped; and shall conform to CSA Standard CAN/CSA-O1 41. The species shown in Table 1 shall be used where treatment is required in accordance with Clause 5.1.

Note: Blocking members cut from full length material do not require a grade stamp.

5.4 Plywood Sheathing

Exterior wall sheathing and preservative treated subfloor shall be unsanded exterior type plywood having at least four plies and shall be limited to the following species: western hemlock, amabilis fir, grand fir, and Coast Douglas fir. All such plywood shall bear markings identifying it as “Hem-Fir” plywood, and shall be

(a) plywood manufactured in accordance with CSA Standard 0121; or

(b) plywood manufactured In accordance with CSA Standard 0151.

Notes:

(1) Plywood marked COFI EXTERIOR DFP.l4em.Fir contains inner plies of only the following species:

western hemlock, arnobilis fir, grand fir, and Coast Douglas fir. Outer plies are Douglas fir. This satisfies the requirement of Clause 5.4.

(2) Plywood marked COFI EXTERIOR CSP-llem-Fir’ contains inner or outer plies of only the following species: western hemlock, omabilis fir, and grand fir, except that it may contain inner plies of Coast Douglas fit. This satisfies the requirements of Clause 5.4.

(3) Plywood conforming to CSA Standard 0721 or CSA Standard 0157 but not identified as “Hem-Fir’ may contain other species. This does not satisfy the requirements of Clause 5.4.

5.5 Fasteners

5.5.1 Nails

Nails for fastening treated material which is used either above or below grade shall be hot-dipped galvanized or stainless steel conforming to CSA Standard Bill. Nail sizes and dimensions shall conform to CSA Standard Bill for common round wire nails and for spiral nails.

5.9.2 Native Soil Where the existing native soil is as permeable as the granular drainage material specified in Clause 5.9.1, such soil may be deemed to satisfy the requirements of Clauses 5.9.1 and 7.2.1. Such soil shall also meet the requirement of Clause 4.3(b) or the footings shall be designed to account for the appropriate lower soil bearing capacity. 5.10 Backfill Native soils having medium or better drainage characteristics as described in Table 2 may be used as backfill material when the backfill must be drained. All backill material placed within 600 mm (24 in) of the foundation walls shall be free of deleterious debris, frozen clumps, and boulders larger than 150 mm (6 in) in diameter. Note: See also Clause 15. 5.11 Manufactured Drainage Layers A manufactured drainage layer shall be a durable composite board or mat with a vertical water permeability at least equal to coarse, clean sand and shall be protected from infiltration of soil particles finer than fine sand. 6. Cutting and Machining 6.1 General Cutting and machining of lumber and plywood should be done prior to treatment. Treated lumber shall not be cut lengthwise or notched. In cases where cutting or boring after treatment is unavoidable, all cuts, holes, and injuries to the surface of treated materials shall be protected by two applications of copper naphthenate preservative. This application shall be by brushing, spraying, or dipping.CSA S406-92 pdf download.