CSA S474-04 pdf download – Concrete structures.

Ductility — the ability of a material to deform and absorb energy beyond its elastic limit (see also System ductility). Durability — the characteristic of a structure to retain its original properties or resistance to long-term deterioration under exposure to the environment and its corrosive and abrasive affects. Fatigue life — the length of time required to satisfy Miner’s rule whereby the ratio of the actual number of load cycles at an allowable stress range to the number of load cycles required to cause a fatigue failure is less than unity. Grouting (of post-tensioning ducts) — filling of post-tensioning ducts with a material that provides corrosion protection to the tendons and has sufficient strength to bond the tendons to the surrounding concrete. Mechanical splice — a device for making in-line connections between reinforcing bars, or for joining a reinforcing bar to a steel component for the purpose of transmitting tensile or compressive forces, or both. Note: The typical mechanical splice is a steel sleeve joined to the reinforcing bar by threading, filler metal, or swaging. Secant modulus (of concrete) — the ratio of the stress in concrete to the strain caused by that stress. Note: Conventionally, a stress of about 0.4 f c is used to determine the secant modulus. Sectional forces — the stress resultants at a section obtained by integrating the stresses over the section. There are six stress resultants for cross-sections of bar-like members: axial load, two shears, torsion, and two moments. There are eight stress resultants for locations in slabs or shells: three membrane forces, three moments, and two out-of-plane shears (see Figure 8.2). Sheath — the form, usually a thin-walled, corrugated tube, used to create a duct in concrete for post-tensioning tendons. Superplasticizer — a chemical admixture used in plastic concrete to greatly increase strength and water reduction, and to produce flowing concrete. Supplementary cementitious materials 4.1.1 All materials used shall comply with the requirements of CSA A23.1, except when such requirements are supplemented or modified by the requirements of this Standard. 4.1.2 Materials not specified in CSA A23.1 may be used if a satisfactory level of performance is experimentally demonstrated and documented. 4.1.3 Testing of all materials shall be performed in accordance with the requirements of CSA A23.2, except when such requirements are supplemented or modified by the requirements of this Standard. 4.1.4 It shall be documented that concrete made from the selected materials has strength, stiffness, density, shrinkage, creep, and thermal properties that fall within the limits required by the design. 4.2 Cements and supplementary cementitious materials 4.2.1 The Portland cement used shall comply with the requirements of CSA A3001. 4.2.2 The blended hydraulic cement used shall comply with the requirements of CSA A3000. 4.2.3 When fly ash, condensed silica fume, pelletized/granulated slag, or natural pozzolans are added to supplement the Portland cement in the concrete, they shall comply with the requirements of CSA A3000. 4.2.4 Supplementary cementitious materials shall be used only if their satisfactory performance is documented.

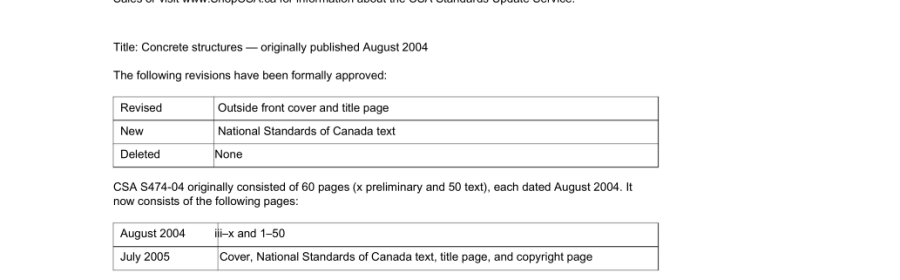

4.7 Prestressing steel and anchorages 4.7.1 All prestressing steel shall comply with the requirements of CSA G279. 4.7.2 It shall be documented that prestressing tendons and prestress anchorages have fatigue characteristics that fall within the limits required by the design. 4.7.3 Stress-relieved strands shall not be used. 4.7.4 When epoxy-coated strand is used, it shall be of the type in which the interstices of the strand are filled with epoxy in accordance with ASTM A 882. 4.7.5 Anchorages, coupling anchorages, and anchorage components shall meet the requirements of CAN/CSA-N287.2. 4.8 Sheathing Sheathing shall be made of rigid or semi-rigid watertight steel or plastic and shall have adequate wall thickness. 4.9 Grout for post-tensioning ducts 4.9.1 Grout for post-tensioning ducts shall satisfy the requirements of Clauses 4.9.2 to 4.9.5 of this Standard and CSA A23.1. 4.9.2 The minimum compressive strength of the grout at 28 days shall be 30 MPa when tested in accordance with Test Method 1B in CSA A23.2.CSA S474-04 pdf download.