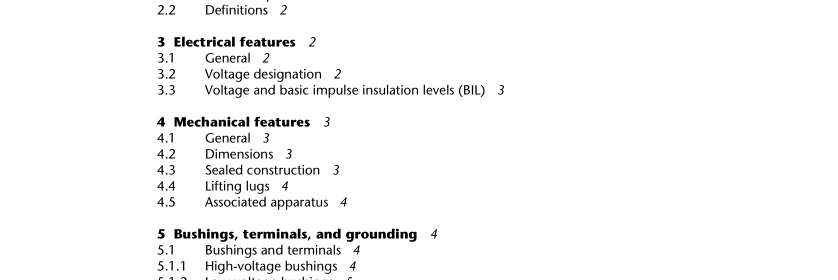

CSA C301.2-06 pdf download – Three-phase submersible distribution transformers.

3.2.1 Voltage designations of the form E 1 GrdY/E (e.g., 41 60 GrdY/2400) indicates a winding having reduced insulation and permanently Y-connected with the transformer neutral grounded (E 1 equals ). 3.3 Voltage and basic impulse insulation levels (BIL) 3.3.1 Preferred high-voltage ratings, BIL requirements, and associated high-voltage terminal components are shown in Table 1 . 3.3.2 Preferred low-voltage ratings and the required BIL rating for transformers are shown in Table 2. 4 Mechanical features 4.1 General 4.1.1 All switch and fuse hardware, accessories, nameplates, and other fixtures exposed to the underground environment shall be corrosion-resistant. 4.1.2 The tank shall have a steel base welded thereto. The base shall support the tank at a minimum distance of 38 mm above the floor. 4.1.3 When external cooling devices are used, fixed mechanical protection shall be provided at the base of the transformer to prevent damage to the cooling devices when lowering the transformer into the vault. 4.2 Dimensions 4.2.1 The transformer assembly includes primary bushings, inserts, secondary terminals, and switch- or fuse-operating handle projections. 4.2.2 Unless otherwise specified by the purchaser, the maximum dimensions of the transformer assembly shall not exceed the values shown in Table 3.

4.3.2 Provision shall be made on all units for the manual release of gas pressures by means of a valve or plug before servicing. 4.3.3 The transformer shall be of sufficient strength to withstand a minimum gauge pressure of 50 kPa without leakage or permanent distortion of the tank. Two 1 /2 in (minimum) pipe plugs or fittings for filling, draining, and pressure testing shall be provided. 4.4 Lifting lugs Four lifting lugs shall be provided diagonally opposite and near the top of the transformer tank. Separate lugs shall be provided for the core, coils, and also for the cover. 4.5 Associated apparatus 4.5.1 Devices such as switches, adapters, separable insulated connectors, and replaceable fuses that are designed for operation after the transformer is in place shall be located so that they can be operated with live-line tools from above. 4.5.2 The external operating mechanism for any high-voltage switch shall include indicators that permit an easy and positive indication of the position of the internal contacts. 5 Bushings, terminals, and grounding 5.1 Bushings and terminals Each transformer shall be supplied with terminals located as shown in Figure 1 . 5.1.1 High-voltage bushings 5.1.1.1 High-voltage bushing wells shall be provided for connection to the distribution system through separable insulated connectors. The bushing wells shall meet the dimensional requirements of IEEE 386. 5.1.1.2 The minimum current-carrying capability of components for the looped primary cable system shall be 200 A (continuous) and 3500 A symmetrical (3 s). Three high-voltage bushing wells shall be supplied for radial-feed units and six for loop-feed units.

5.1.1.5 For GrdY primary, the high-voltage neutral shall be connected internally to the tank cover at the locations of the external high-voltage ground terminals designated and marked H0 unless an isolated X0H0 bushing is specified by the purchaser. These internal connections shall be accessible when the handhole cover is removed. 5.1.2 Low-voltage bushings 5.1.2.1 Low-voltage terminals for all sizes of transformers shall be the spade type, in accordance with CSA C2.1 , except that the terminals shall be made of tinned copper. 5.1.2.2 The low-voltage neutral, when supplied, shall be connected to an insulated neutral terminal designated X0 and having a current-carrying capacity equal to the other low-voltage terminals. 5.2 Grounding 5.2.1 Each transformer shall be provided with two stainless steel spade-type terminals welded to the tank cover with minimum dimensions as shown in Figure 1 . When the primary winding is connected GrdY, the terminals shall be designated and marked H0 and internally interconnected; otherwise, these terminals shall not be designated and marked and do not need to be interconnected. 5.2.2 The grounding terminals shall be located on the tank cover, on opposite sides of the longitudinal centreline, and adjacent to the handhole so that internal connections to H0 are accessible. One H0 terminal shall also be as close as practicable to the insulated X0 terminal (when supplied). 5.2.3 When the low-voltage winding is connected Y or GrdY, the neutral terminal X0 shall be connected to the grounding spade terminal with a waterproofed conductor of suitable current-carrying capacity.CSA C301.2-06 pdf download.