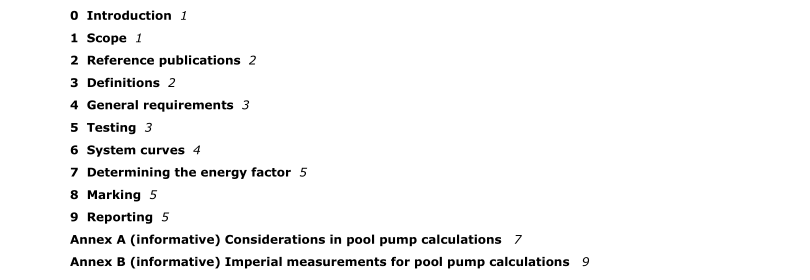

CSA C840-12 pdf download – Performance of pool pumps.

1.6 The values given in SI units are the units of record for the purposes of this Standard. The values given in parentheses are for information and comparison only. 2 Reference publications This Standard refers to the following publications, and where such reference is made, it shall be to the edition listed below, including all amendments published hereto. CSA (Canadian Standards Association) CAN/CSA-C22.2 No. 108-01 (R2010) Liquid pumps ANSI (American National Standards Institute) ANSI/HI 1.6-2000 Centrifugal Pump Tests APSP (Association of Pool and Spa Professionals) APSP-15 (Draft 2010 – Revision 11-D4) Standard for Energy Efficiency for Residential Inground Swimming Pools, and Spas CEC (California Energy Commission) CEC-400-2010-012 (CEC Title 20) CEC 2010 Appliance Efficiency Regulations IEEE (Institute of Electrical and Electronics Engineers) 114-2001 Standard Test Procedure for Single-Phase Induction Motors 3 Definitions The following definitions shall apply in this Standard Centrifugal pump — a kinetic machine converting mechanical energy into hydraulic energy through centrifugal motion.

Energy factor — water delivered divided by motor energy consumed at a particular head pressure, measured in litres/W-hr (gal/W-hr). Flow rate — the volume of water transported in a given period of time, usually measured in litres per minute (US gallons per minute). Gallon — for the purposes of this Standard, the liquid measure “gallon” refers to one US gallon. Multi-speed — a pump motor capable of operating at two or more speeds and includes two-speed, three-speed, and variable-speed. Nameplate power — the motor horsepower as listed on the serial plate. This is the measure by which a pump unit is typically sold. Operating point — a point of intersection where the pump performance curve crosses one of the system curves (A, B or C). Permanently installed swimming pool — a pool constructed in such a manner that it cannot be disassembled for storage. Pump — a means for pumping liquid, excluding a driver. Pump unit — a combination of a pump and an electric motor. Storable swimming pool — a pool constructed in such a manner that it can be readily disassembled for storage and reassembled to its original integrity. System curve — a graphical representation of the relationship between flow rate and total dynamic head for a given pump unit. Total dynamic head (TDH) (or head) — the output pressure of the pump that overcomes all of the friction losses and pressure drops in the piping system.

6 System curves 6.1 Three system curves shall be calculated as follows: Curve A: H = 0.000355 x F² Curve B: H = 0.001064 x F² Curve C: H = 0.000174 x F² Where: H = the total system head in metres of water (m) F = the flow rate in litres per minute (lpm) 6.2 For each system curve (A, B, or C), the pump TDH (head) shall be adjusted until the flow and TDH lie on the curve. The following data shall be calculated and reported: Motor nominal speed (RPM) Flow (litres per minute) Power (watts) Energy Factor (litres per watt hour) Where the Energy Factor (EF) is calculated as: EF = Flow (lpm) * 60 / Power (watts) 6.3 For 2-speed, 3-speed or other multi-speed pumps, with fixed non-adjustable speeds, the intersection point of the pump performance curve with each system curve shall be tested and reported at each available speed. The intersect data required in Cause 6.2 shall be reported for each speed and each system curve. 6.4 For variable speed pumps, the intersection point of the pump performance curve with each system curve shall be tested and reported. The intersect data required in Clause 6.2 shall be reported for the highest speed, lowest speed, and the best energy factor speed as determined by the manufacturer.CSA C840-12 pdf download.