CSA Z259.18:19 pdf download – Counterweighted guardrail systems.

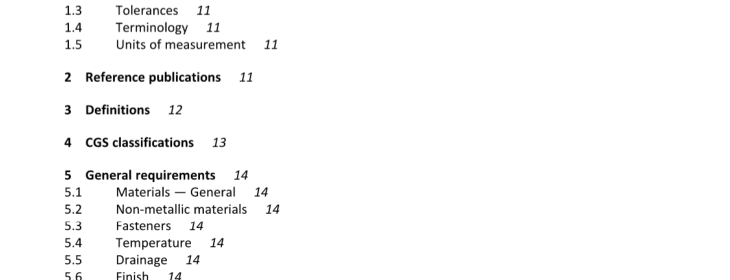

5 General requirements

5.1 Materials — General

All materials shall be designed for use in the environments where they are permitted to be installed by the manufacturer. The selection and installation methods shall take into account wind, heat, cold, moisture, vibration, ultraviolet light, corrosive environments, and other environmental conditions that could be expected to affect the strength and performance of the CGS.

All components shall be durable and have similar longevity unless a specified maintenance plan is provided in accordance with Clause 9.2 j).

5.2 Non-metallic materials

The manufacturer shall issue a declaration of conformity that non-metallic materials that can be degraded by exposure to sunlight or other environmental conditions are protected against such degradation by proper shielding or other suitable means.

5.3 Fasteners

The manufacturer shall issue a declaration of conformity that all components of the CGS, including fasteners, do not create any combination of metals that have the potential to cause an adverse galvanic reaction.

All fasteners connecting counterweights and railings or railing elements shall be rated for the applied loads.

5.4 Temperature

The manufacturer shall issue a declaration of conformity that the material selected for all components of the CGS have durability, reliability, and impact resistance during operation in ambient temperatures from —35 to +65 C (—31 to +149 F).

5.5 Drainage

All components shall be free draining and prevent adverse water accumulation within the rail, the post, and counterweight components.

5.6 Finish

The finish of all components of the CGS shall be free of deposits (scale, rust) of foreign matter other than applied protective coatings, and free of sharp edges.

5.7 Welded assembly

When steel components are welded, the welding shall be performed by companies complying with CSA W47.1 and shall meet or exceed the requirements of CSA W59, or ANSI AWS D1.1/D1.1M,

When aluminum components are welded, the welding shall be performed by companies complying with CSA W47.2 and shall meet or exceed the requirements of CSA W59.2, or ANSI AWS D1.2/D1.2M.

6 Design requirements

6.1 Configuration

The top rail height shall be between 990 and 1143 mm (38.9 and 45 In) from the top of the rail to the walking surface.

Note: An authority having jurisdiction might require different top roil heights. The values stated here ore for the purpose of compliance with the requirements of this Standard.

6.1.2

Intermediate rails shall be located so that the gap between any two rails shall not exceed 480 mm

(18.9 in).

The gap between the lowest intermediate rail and the walking surface shall not exceed 530 mm

(20.8 in).

Notes:

1) In some cases, the addition of a toe board might be required by the authority having jurisdiction.

2) In many cases, a toe board is not required if a similar/comparable feature exists.

3) There can be instances that require two intermediate rails.

6.1.3

Cantilevered sections of railing at the ends or corner shall not extend more than 500 mm (19.7 in) beyond the vertical post.

6.2 Counterweights

6.2.1

The materials of counterweight shall be as follows:

a) for a Class I CGS, the counterweight shall not be granular or fluid materials such as sand or water. Each counterweight shall be capable of being secured against accidental displacement (see Annex A); and

b) for a Class II CGS, it may be solid, granular, or fluid. A counterweight composed of granular or fluid materials shall be securely contained in such a way that the mass of the counterweight is maintained over the duration of the intended use.

6.2.2

All components of the CGS shall be secured to resist forces in any direction so that they will not release under the usage for which the system has been designed.

6.3 Strength

A CGS system shall have strength and deflection, and other characteristics such that it is capable of

meeting the requirement of Clause 7.CSA Z259.18:19 pdf download.